Introduction:

In the world of modern engineering, materials play a crucial role in ensuring the strength, durability, and functionality of various structures and components. Among the many materials available, titanium has emerged as a remarkable metal with exceptional properties. Titanium plate and pipes, in particular, have gained significant popularity due to their versatility and superior performance in numerous industries. In this blog, we will delve into the fascinating world of titanium and explore the applications, benefits, and features of titanium plates and pipes.

Titanium Plates:

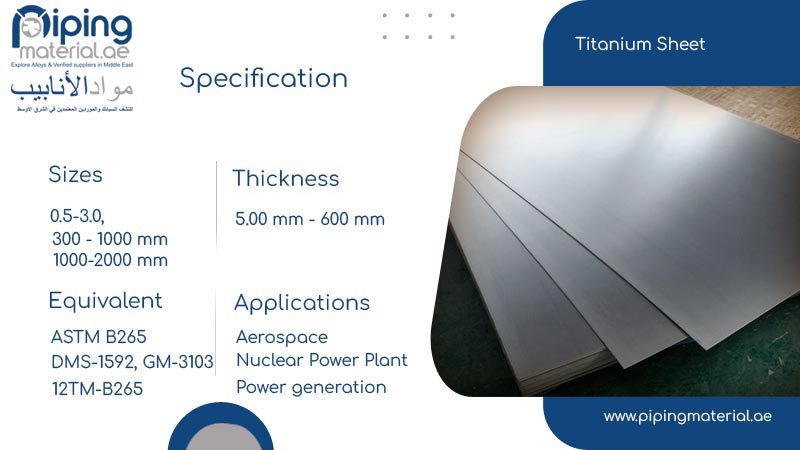

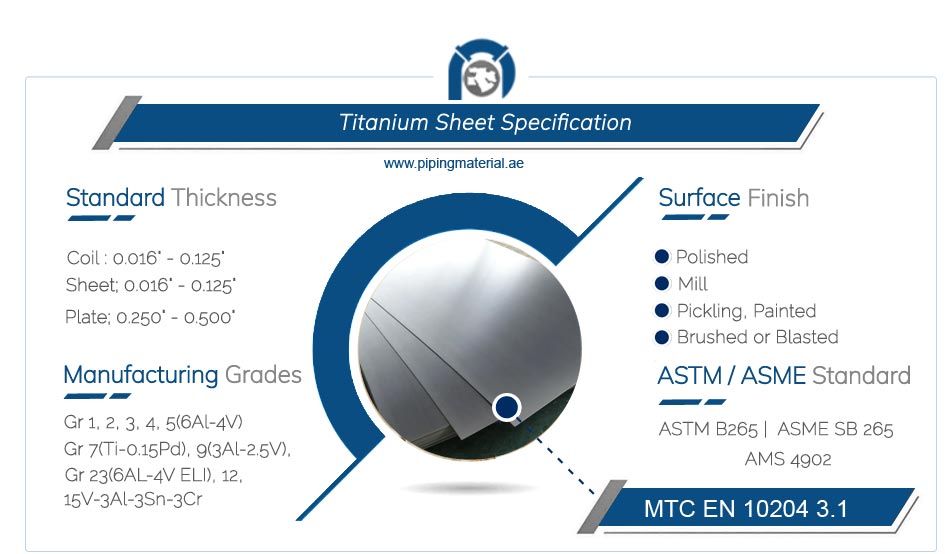

Titanium plates are flat, thin sheets of titanium metal that are manufactured through various processes, including hot rolling, cold rolling, and annealing. Here are some key aspects of titanium plates:

.jpg)

Lightweight yet Strong:

One of the most outstanding features of titanium plates is their exceptional strength-to-weight ratio. Titanium is known to be as strong as steel but weighs approximately 50% less. This characteristic makes titanium plates a favored choice in aerospace, automotive, and marine industries, where weight reduction is critical without compromising structural integrity.Corrosion Resistance:

Titanium plates possess remarkable resistance to corrosion, even in harsh environments. This resistance is due to the formation of a thin, protective oxide layer on the surface of the metal. As a result, titanium plates are extensively used in chemical processing, offshore oil and gas exploration, and desalination plants, where exposure to corrosive substances is common.

Biocompatibility:

Another notable advantage of titanium plates is their biocompatibility. This property makes them suitable for medical applications such as orthopedic implants, dental prosthetics, and surgical instruments. Titanium’s ability to integrate with human bone tissue, coupled with its corrosion resistance, ensures a higher success rate in implant procedures.

Titanium Pipes:

Titanium pipe, also known as titanium tubes, are cylindrical structures made from titanium. They are widely employed in various industries due to their exceptional properties:

High Strength and Heat Resistance:

Similar to titanium plates, titanium pipes exhibit exceptional strength and heat resistance. This makes them ideal for applications in industries such as power generation, chemical processing, and oil and gas exploration. Titanium pipes can withstand high-pressure environments and maintain their structural integrity at elevated temperatures, making them indispensable in critical operations.

Low Thermal Expansion:

Titanium pipes have a low coefficient of thermal expansion, which means they expand and contract minimally under temperature variations. This characteristic allows for more stable and predictable performance, making them suitable for applications where temperature changes are frequent, such as heat exchangers and cryogenic systems.

Superior Conductivity:

In certain industries, such as the aerospace sector, titanium pipes are used to transport fluids and gases that require efficient heat transfer. Titanium’s excellent thermal conductivity ensures effective heat exchange and prevents temperature imbalances, improving overall system performance.

Conclusion:

Titanium plates and pipes have revolutionized various industries with their exceptional properties, combining strength, lightweight design, corrosion resistance, biocompatibility, and thermal stability. From aerospace to medical and chemical sectors, titanium has found its way into critical applications that demand reliability and longevity. As research and technological advancements continue, we can expect titanium’s prominence to grow even further, unlocking new possibilities for innovation and pushing the boundaries of engineering achievements.

Congrats! You’ve Finished This Blog.